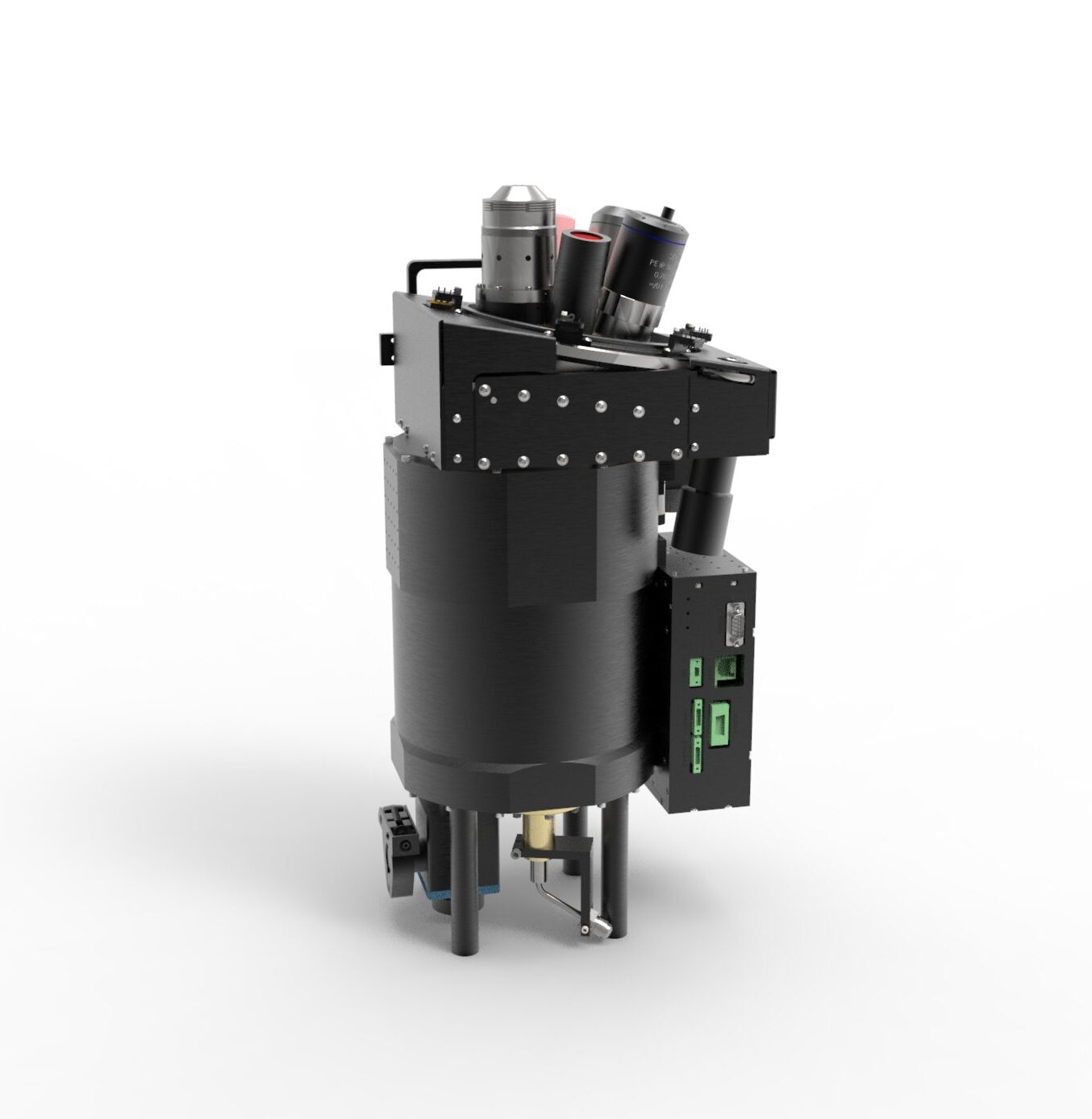

The IREM-IV photon emission microscope is ready to solve your toughest IR photon emission FA problems. For over 20 years, we have worked with the world’s leading semiconductor companies to provide the most sensitive photon emission FA tools.

Photon Emission Microscope System Features

- Inverted Microscope Design

- Allows docking with all common testers

- Optional Wafer Probing Capability

- Optional Laser Sensor

- Measures DUT surface tilt/profile

- Modular Upgrade Path/Optical Expansion Port

- Suitable for integrating external laser scanned or other optical systems

IREM-IV Camera

- 1016 x 1016px LN2-Cooled MCT Array

- 18 micron pixel size

- 440 – 2500nm Spectral Range

- 6 Position Motorized Lens Turret

- 6 Position Dual Internal Cooled Filter/Aperture Wheels

- >20 Hour LN2 Hold time

Motion System

- 25nm Resolution

- 100mm Range (x-y-z)

- Damped Vibration Isolation

- Motorized Sample Tip-Tilt Option

AIRIS Software

Controlling the IREM photon emission microscope is easy with AIRIS software which also provides comprehensive image analysis and test project management tools:

- Navigate to any point on your sample by clicking on any open image

- Point database for rapid return to multiple points of interest

- Create large field-of-view, high resolution mosaic images

- Automate measurement tasks with AIRIS scripting

Project windows provide separate work areas for all your AIRIS data:

- Organize data and notes into project workspaces that can be reopened later.

- Create sticky notes anywhere in the project window with the click of a button. Use them to summarize results, test conditions, etc.

System Dimensions

Microscope

- 810mm x 876mm x 813mm

- 160kg

Electronics Rack

- 610mm x 1283mm x 762mm

- 90kg