Temperature Controlled Stage

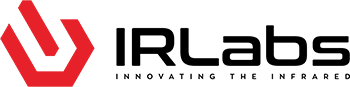

A temperature controlled stage is used when a testing is needed at a temperature higher than that of the base temperature of the cold plate. These can be used in both nitrogen, helium and closed cycle systems. A temperature controlled stage is mounted to the system’s primary cold plate and supported by low thermal conductivity materials such as G-10 fiberglass or stainless steel. The temperature of the stage is controlled to a setpoint temperature with an external temperature controller that is connected to a heater and temperature sensor mounted to the stage. This allows very stable and precise control of the stage temperature.

The thermal contact between the temperature controlled stage and the main cold plate are controlled using a mechanical heat switch. This allows the conductive contact between the main cold plate and the temperature stage to be optimized to reduce thermal load on the system and stability of the temperature controlled stage.

Features

- Precision and stability typically better than +/- 0.005K over extended periods.

- Simple operation

- Can accommodate a wide range of requirements

Pumping Manifold

A pumping manifold is needed when pumping on cryogenic baths to reduce the vapor pressure and temperature of a system. For example a nitrogen system is typically at 77 K but if the vapor pressure is reduced by pumping on the bath temperatures as low as 55 K can be achieved. Helium can similarly be dropped from 4.2 K to about 1.5 K by pumping on the bath. When pumping on a cryogenic bath a gradual pump down is critical. A pump down that is too fast will pull cold cryogens into your pumping system and severely decrease your system hold time. For these reasons a pumping manifold is used. The manifold is connected between you the dewar and a mechanical backing pump and has a series of valves to control the rate of pump down.

Features

- Simple operation

- Reduces cryogen consumption

- Allows for operating LN2 at ~55 K and LHe at 1.5 K

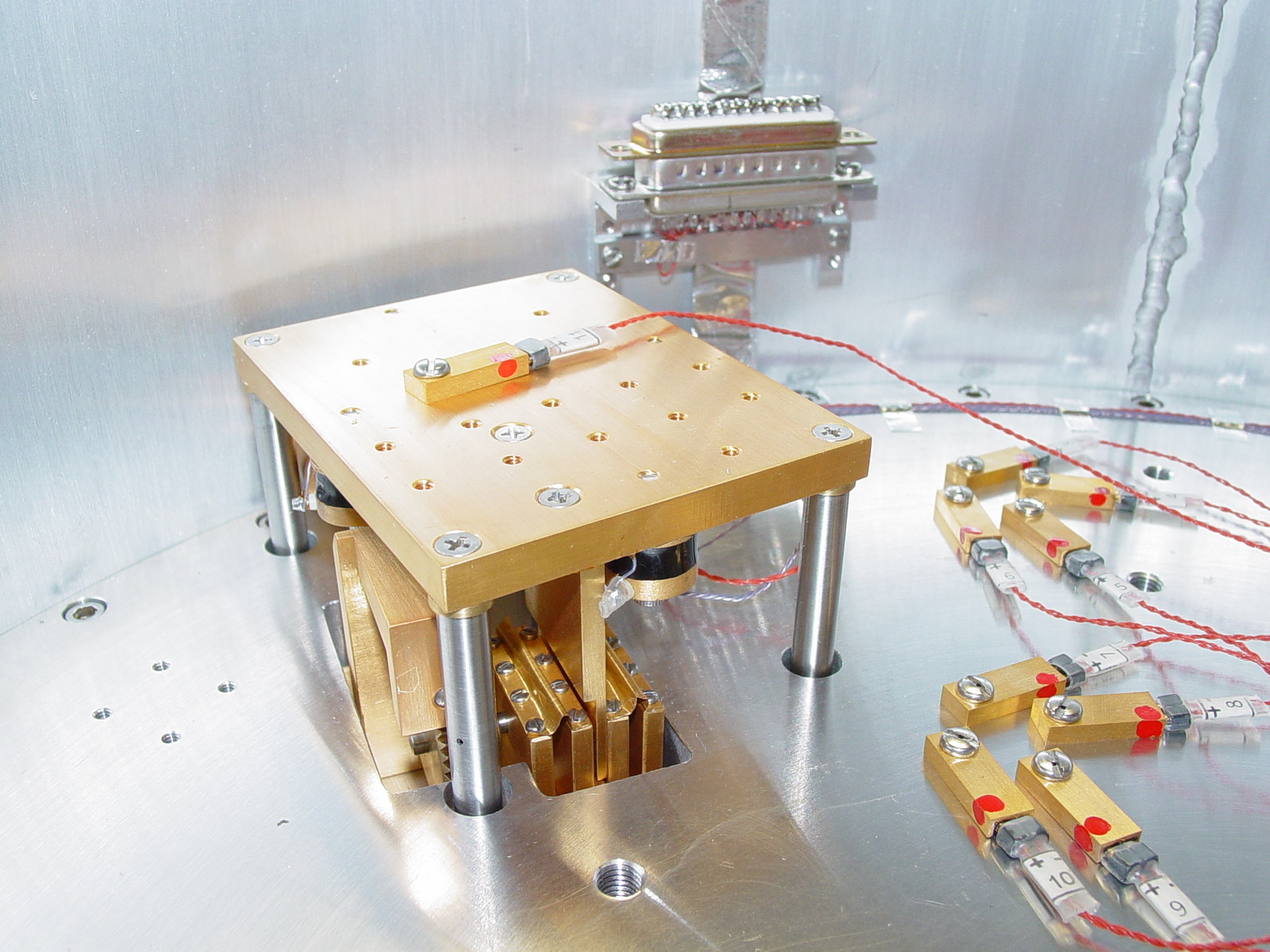

Vacuum Glands

A vacuum gland is used to pass a control shaft through the vacuum case while the system is kept cold and under vacuum. The vacuum gland with control shaft are hermetically sealed to the vacuum case, the shaft can then be pushed into the dewar to move mechanical devices such as a heat switch or filter wheel then pulled back out to break thermal contact. This is a simple and economic method for moving devices inside the dewar.

Features

- Easy way to control filter wheels, heat switches, slides

- Simple, inexpensive, reliable

LHe Transfer Tubes

A vacuum jacketed transfer tube is required for filling LHe systems. The transfer tube is used to efficiently transport LHe from a storage dewar into the research cryostat.

Features

- Flexible design to accommodate a wide variety of storage dewars and lab setups

- Efficient transfer to reduce consumption of expensive LHe

Heater Buttons

Our heater buttons are designed for cryogenic operation. These devices are used for temperature controlled stages and quick warm up circuits. Standard heater buttons are 25 Ohms and built for up to 1 Amp current. This is a typical standard used for commercial temperature controllers.

Features

- Simple operation

- Industry standard configuration

- Custom configurations available

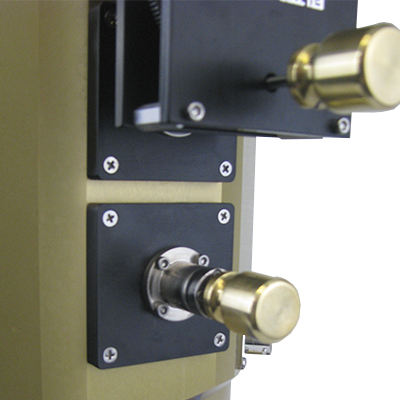

Potted Cable Flange

A potted cable flange is required when a cable needs to pass through a vacuum barrier such as a dewar wall without using an intermediate electrical connector. These flanges are typically used for focal plane array (FPA) ribbon cables that require an uninterrupted connection between the detector mounted inside the dewar and the readout electronics mounted outside the dewar. In these applications, an intermediate bulkhead electrical connection cannot be used. Instead, the solution is to pot the cable into a custom flange, passing the ribbon cable through the flange and then encapsulating the cable in place in a way that creates a rigid hermetic seal. The finished flange can be sealed with a standard O-ring to the dewar vacuum case. IRLabs has experience in flange design, potting materials, and sealing procedures that will ensure a long-lasting hermetic seal.

Features:

- Allows hermetic sealing of ribbon cables through vacuum case

- Long-lasting hermetic seal

- O-ring sealed flange can be removed and reinstalled without damage to cable

- All flanges are leak checked with helium mass spectrometer

Autofill Controller

Program the AutoFill Controller to automate liquid nitrogen fills. Set fill time and duration to autofill dewars, or use the controller to perform a manual fill. Equipped with an overfill sensor to detect and stop filling when your dewar has reached capacity. The Autofill Controller can be used with IRLabs NDV and NDL series dewars, such as those found on Bruker Spectrometers or on the IREM tool. It can also be fitted to work with most other pour-fill dewars, including competitor systems.

Features:

- Easy set up and retrofit to existing systems

- Audible alarm during filling

- Digital touch screen display that allows the user to set the number of fills per day, their start times, and their durations

- Easy, one-time automated calibration of the overfill sensor