Overview

IRLabs collaborates with leading research organizations to contribute technical expertise as a trusted partner in projects such as the Ice Giants Net Flux Radiometer (NFR) instrument being developed by NASA Goddard Space Flight Center to further exploration of exoplanetary systems. The NFR project team, led by NASA GSFC, included University of Maryland, University of Oxford, and Catholic University of America.

If chosen for a future mission, the NFR onboard a probe will descend deep into the atmospheres of either or both of the ice giant planets Neptune and Uranus, depending on the scope of the mission, to measure planetary radiation flux as a function of altitude. Net flux is the difference between upward and downward radiative power. Measuring net flux will help scientists study radiative heating or cooling, solar energy deposition, and composition of the local atmosphere. The NFR instrument accomplishes this by measuring background optical radiation in seven spectral bands as it descends. The detector head rotates during descent to make observations in several directions including up and down. An array of Winston cones is the perfect choice to collect the optical radiation and concentrate it on an array of single-point detectors to optimize signal-to-noise ratio. Each cone and detector measure a specific optical band ranging from 0.2 µm to 300 µm.

NASA GSFC worked with IRLabs to develop laboratory proof of concept experiments using a pair of Winston cones and detectors cooled in a standard liquid nitrogen cooled dewar. Successful demonstration of the concept led to additional funding and IRLabs being selected to design and build a miniature “micro-vessel” vacuum housing for the two-cone system which was later expanded to a seven-cone assembly to measure energy flux in all seven spectral channels. IRLabs also contributed to a final design iteration that is awaiting funding.

Watch Video

NFR in being studied for possible use in entry probe missions to ice giants Nepture (above) and/or Uranus.

Image credit: NASA/JPL.

Key Facts

Project: Ice Giant Net Flux Radiometer

Clients: NASA Goddard Space Flight Center

Project Location: United States

Application: Astronomy

IRLabs Product: Custom vacuum micro-vessel and Winston cone assembly for detector array in space-qualified instrument

Challenges

The NFR is designed for space flight, but it must also survive the launch phase and operate reliably while descending on the probe through the ice giant atmosphere. IRLabs faced the following engineering requirements and challenges:

- Configuring seven spectral channels with a clear, unobstructed 5-degree clear field of view for each channel to meet the compact size and light weight required for space travel.

- Wide 170 K to 388 K operating temperature range during descent through the ice giant atmospheres while meeting NASA’s planetary protection bakeout protocols.

- Wide pressure range from 1 to 10 bar with a known calculated leak rate throughout the entire journey.

- Easy access to ports for disassembly and reassembly during lab research and testing.

Solutions

IRLabs applied decades of experience in IR astronomy to meet NASA’s requirements. Our engineering team worked closely with the NASA GSFC project team to design solutions for the unique specifications for the NFR. Following are some highlights of overcoming several design challenges.

Material Sourcing and Manufacturing Techniques For High Strength, Low Weight

We met size and weight requirements by using high strength, lightweight materials and advanced machining and production processes to reduce mass and number of components. All micro-vessel structural components are titanium for high strength and corrosion resistance. A286 steel alloy hardware and laser welding techniques were employed to fasten the assembly together. The Winston cones were produced using an additive electroforming process, where nickel is deposited over a mandrel form and then the mandrel is removed for final machining.

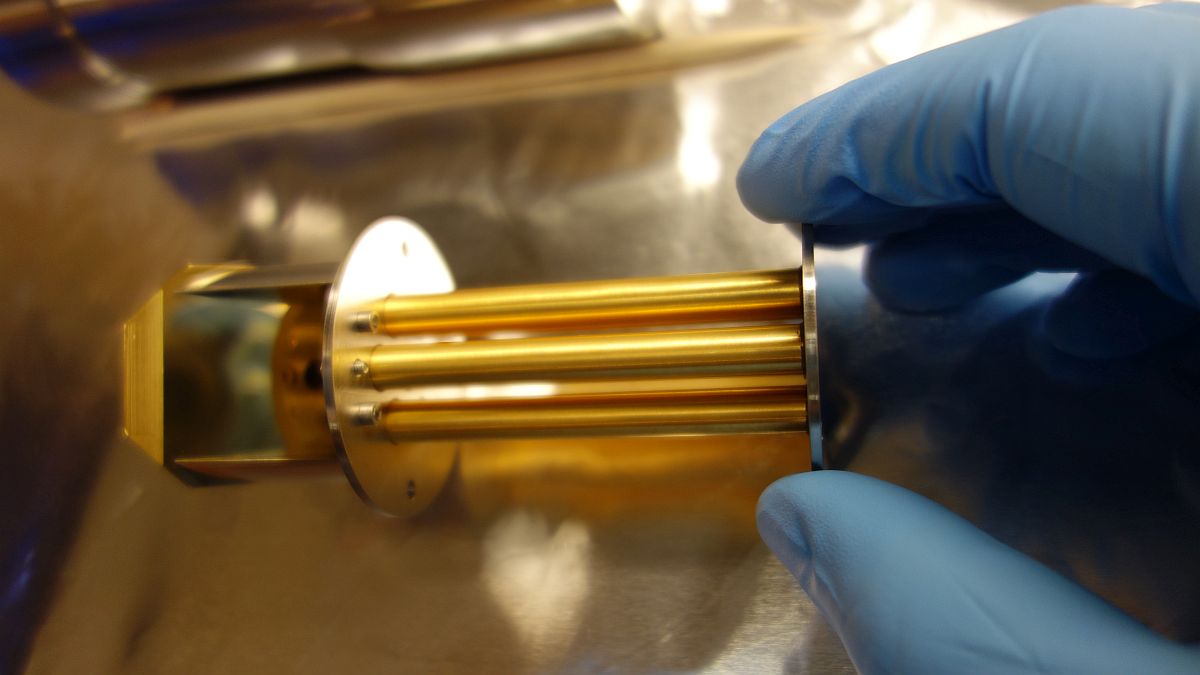

Unique Winston Cone Assembly Method

Each Winston cone observed the outside environment through a window port and had to maintain alignment with its associated detector element. We designed a method to hold the cone assembly in specific alignment to the housing, to the window port, and to concentrate light on the detector array. The lightweight, compact, and structurally rigid subassembly was engineered to withstand extreme pressure differentials while maintaining ease of assembly and testing.

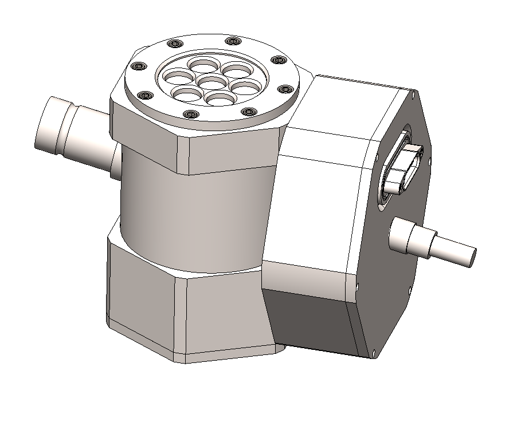

Final Window Port Design Helps Meet Size and Weight Limits, Reduces Cost

The seven Winston cones and detectors observe the outside environment through a window port that must provide an unobstructed 5-degree field of view and transmit radiation over the 0.2-300 µm spectral range. Design of the window port is a key factor affecting overall size and weight of the instrument.

IRLabs worked with NASA GSFC to design iterations of window port concepts. One prototype used a single diamond window that could transmit the entire spectral range. Compared to previous designs, this concept reduced mass by almost 15% and provided substantial cost savings. The window was fabricated by chemical vapor deposition (CVD), was corrosion resistant, and met all operating temperature and pressure requirements.

Evaluation of the diamond window prototype led to concerns over the large difference in coefficient of thermal expansion between the diamond material and titanium micro-vessel. The concern was that differences in expansion over the wide temperature range would stress the window and risk fracture and loss of vacuum seal. Attempts to mitigate this risk using a molybdenum window seat were found to add too much mass and cost.

This led to a final design iteration that made it feasible to return to separate windows for each cone. Eliminating a folding mirror within the micro-vessel reduced the optical path length from window to cone, which reduced size, mass, and cost.

Micro-vessel Design for Benchwork and Mission

The micro-vessel needed to be accessible for researchers to assemble and disassemble during laboratory testing. The vacuum valve was designed for lab access using rubber O-rings and an actuator to evacuate the inside during bench work, then replaced with a permanent mechanical connection for missions. For access to the detector array and PCB, the exit port was designed with multiple rubber O-rings for lab work and will be replaced with metal-coated O-rings for missions.

Our work on the micro-vessel and optics for NASA’s NFR demonstrates IRLabs’ ability to solve unique challenges presented by scientific exploration and work in collaboration with our client. Many challenges were solved including selection of lightweight but durable materials and developing innovative Winston cone assembly methods. For NASA and other clients in the scientific community, IRLabs is known for its ability to solve design challenges with our engineering talent and manufacturing capabilities.

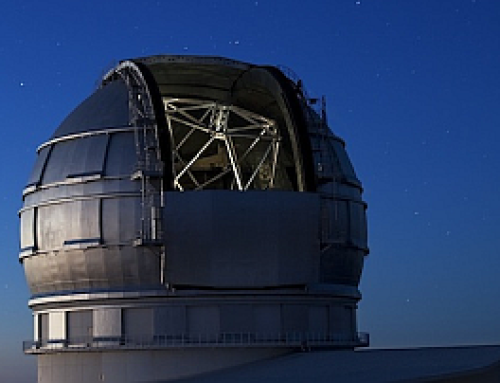

Compact array of seven Winston cones (one for each spectral band). The cones concentrate light onto an array of seven detectors.

Micro-vessel prototype with a seven internal Winston cones and a single diamond window port.

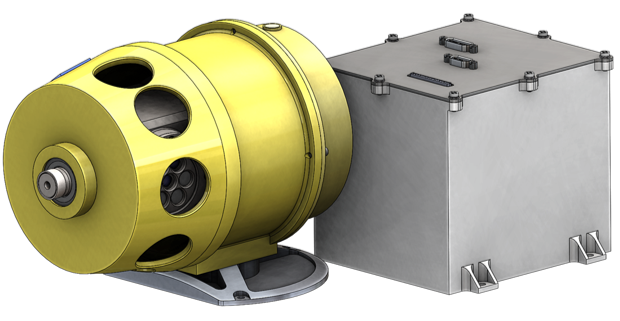

Current design iterations returns to independent windows for each channel but maintains a compact micro-vessel that can rotate within the probe housing and observe flux in a number of directions as the probe descends through the ice giant atmosphere.

More Information and Images:

- NASA’s Ice Giants Pre-decadal Mission Survey

- Ice Giant Systems

- NFR Recorded Presentation

- Advanced Net Flux Radiometer Focal Plane Assembly for Ice Giants Research Team:

- Principal Investigator: Shahid Aslam, NASA GSFC

- Co-Investigators: Richard K. Achterberg, UMCP: Valeria Cottini, UMCP, Nicolas Gorius, CU; Tilak Hewagama, UMCP; Conor A. Nixon, NASA GSFC; Geronimo Villanueva, NASA GSFC; and Gerard Quilligan, NASA GSFC.

- Collaborators: Patrick Irwin, Oxford and Amy A. Simon, NASA GSFC

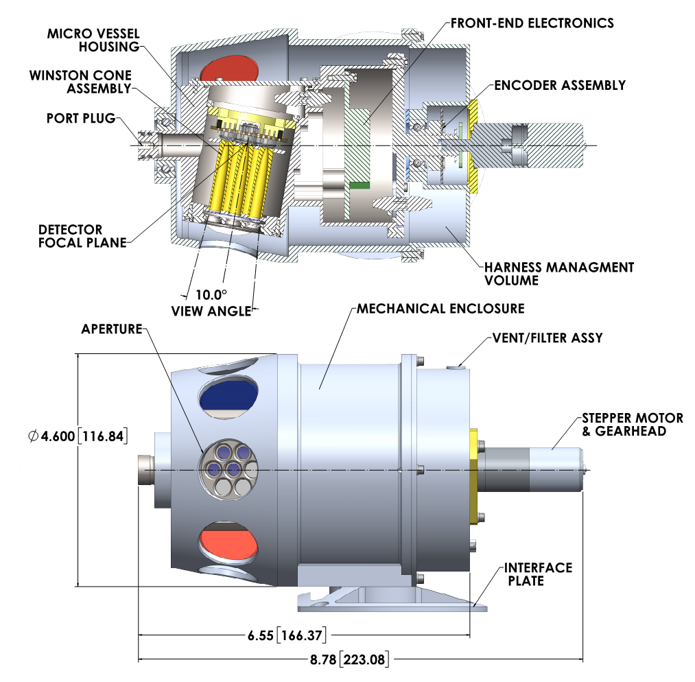

Configuration of the micro-vessel with seven Winston cone block in the probe. The instrument is designed to use a seven-channel thermopile detector focal plane and a stepper motor to rotate the micro-vessel to five viewing angles, -80⁰, -45⁰, 0⁰, 50⁰, and 135⁰, and two apertures to calibrate to hot and cold targets.

Image provided courtesy of NASA GFSC.

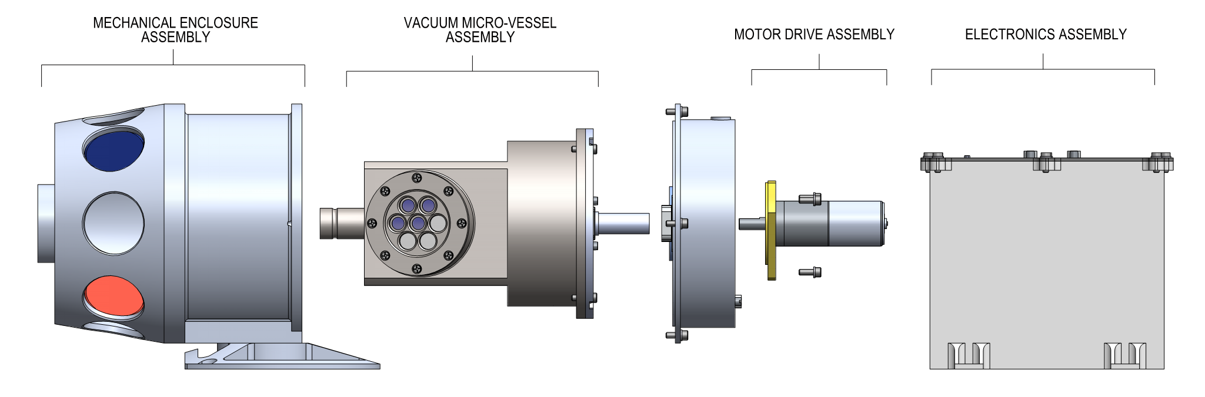

Probe system components. IRLabs designed the vacuum micro-vessel with Winston cones assembly.

Image provided courtesy of NASA GFSC.