Overview

The purpose of the project was to design and produce a cryostat to simultaneously characterize four MCT focal plane arrays. These FPAs will be used in the NEO Surveyor, a space-based IR telescope to survey the solar system for near-earth objects.

Watch Video

Key Facts

Project: NEO Surveyor

Project Location: United States

Application: Astronomy, Focal Plane Array

IRLabs’ Product: Custom GM cryostat system

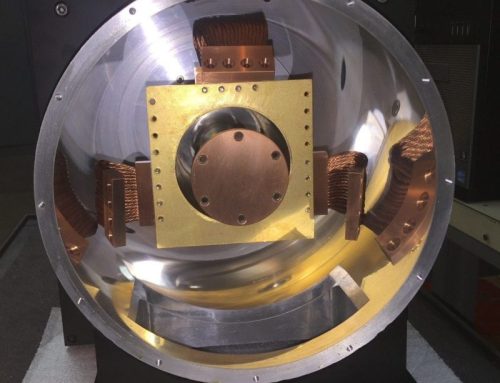

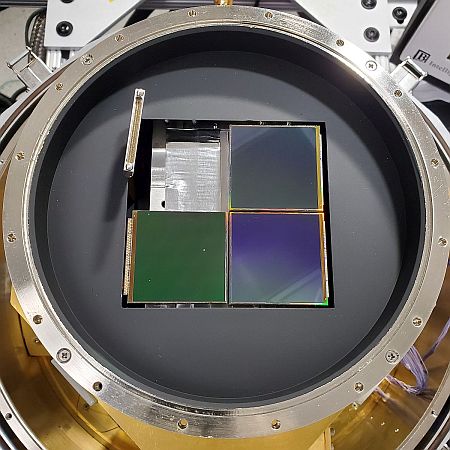

Example of cold plate assembly

of a custom cryostat.

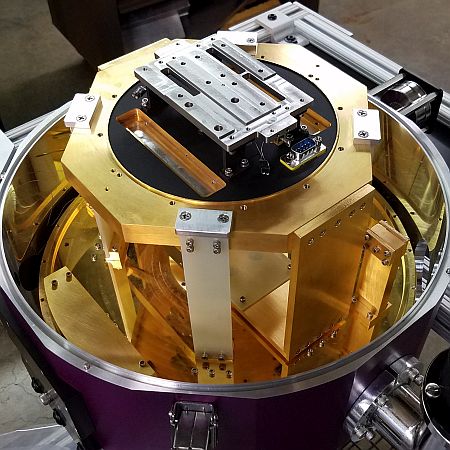

Example of four MCT FPA installed in a custom cryostat.

Challenges

The challenges in characterizing the detectors were in three key areas: illumination uniformity, light tightness, and temperature stability.

- Illumination uniformity across a large focal plane array (> 98% uniformity across ~3.1” x 3.1” active area)

- Light tightness and low thermal background for LWIR dark current measurements (<10e-/s/pixel background flux for a 11um-cutoff detector)

- Temperature stability (+/- <10mK over 7 day test cycle):

- All detectors, electronics and optics must be thermally stable within the 1 meter tall instrument

- Instrument must maintain temperature within +/- 0.010 K during operation (Test temperature = 30-77K, <10mK stability)

- Temperature stability had to be maintained over 7 day test cycle. Instrument testing cycles can last several weeks.

Solution

Starting with the statement of work, we identified the design-driving criteria – illumination uniformity across the large focal plane as defined by the four Teledyne H2RG detectors. We met initially with our client’s team to identify their concerns and worked closely with them through concept design, preliminary design review, critical design review, and fabrication to produce a custom, closed cycle GM refrigerator with a 12-inch cold plate that can test four detectors at once.

Customization included:

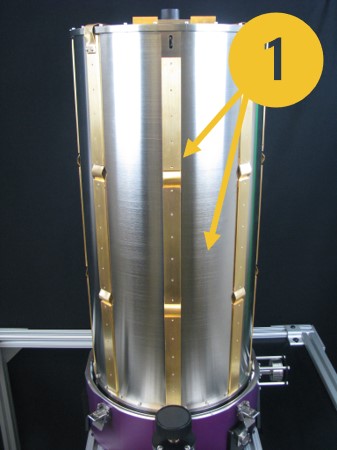

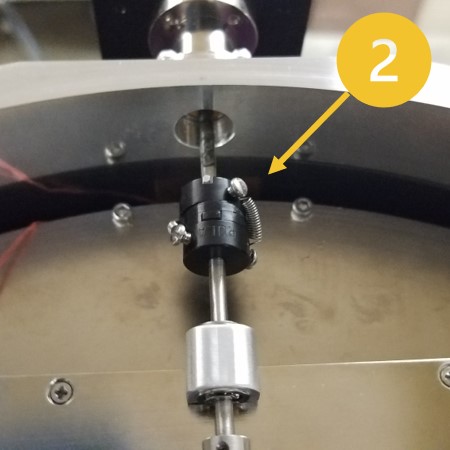

- Custom radiation shields and copper ribbing to efficiently pull heat out of the system, and special couplers for the filter wheel to maintain alignment and tight tolerances over system length from aperture to the cold plate. See examples 1 and 2 below.

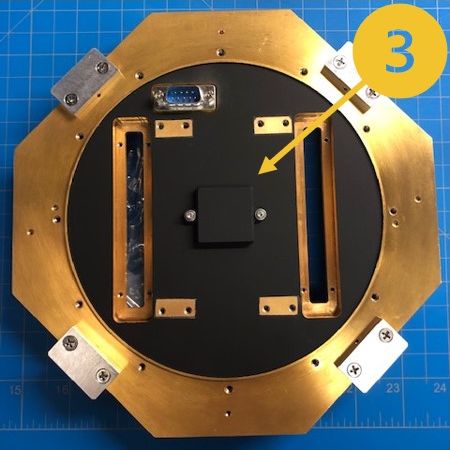

- Nickel-coated and black absorptive polyurethane coating (Aeroglaze) to reduce any light reflections or stray light from detection. See example 3 below.

- Use of molybdenum, titanium, and Invar for stability at cryogenic applications and for thermal conductivity properties.

- Special feedthroughs for air venting without light entry.

- Latches and disconnects for convenient access for maintenance and service. See example 4 below.

- Modular case for the client to add an integrating sphere for more uniform illumination of the detectors when needed.

In addition to the custom cryostat, we are performing tests of off-the-shelf shutters and modifications required for successful optomechanical operation of a very fast cryogenic shutter.

Example of custom radiation shield and

copper ribbing to pull heat out of the system.

Example of special filter wheel coupler to maintain

tight tolerances over system length.

Example of black absorptive polyurethane coating

to reduce light reflections or stray light.

Example of custom cryostat with latches

and handles for convenient access.